Table of Contents

ToggleImagine turning your wildest ideas into reality with just the push of a button. That’s the magic of 3D printing! This revolutionary technology lets anyone—from hobbyists to aspiring inventors—create everything from quirky gadgets to life-saving medical devices. If you’ve ever dreamed of seeing your doodles leap off the page, you’re in for a treat.

Understanding 3D Printing

3D printing represents a revolutionary technique that transforms digital designs into physical objects. This process appeals to many due to its versatility and the ability to bring diverse ideas to fruition.

What Is 3D Printing?

3D printing refers to additive manufacturing technology that creates objects layer by layer using various materials. Common materials include plastic, metal, and resin. This innovative method unlocks creativity across different sectors, making it ideal for producing prototypes and custom designs.

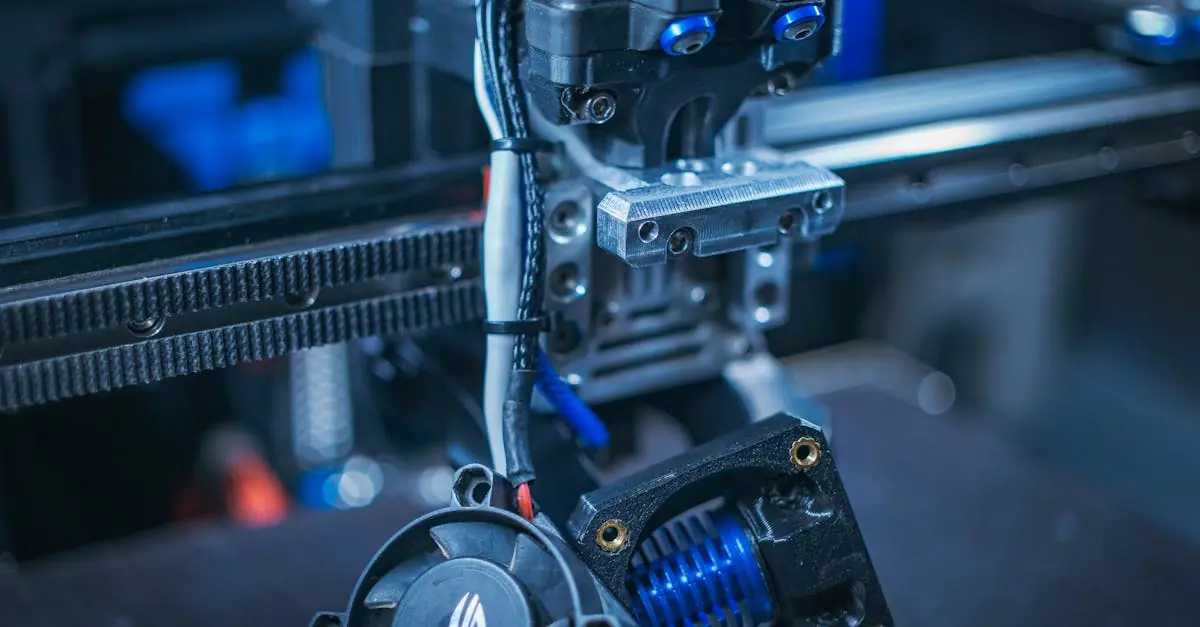

How Does 3D Printing Work?

3D printing operates through a series of systematic steps. First, a digital model is designed using computer-aided design software. Next, this model is sliced into thin layers, allowing the printer to build the object from the bottom up. As each layer solidifies, the final product gradually takes shape. Advanced printers utilize different methods, such as FDM and SLA, each suited for specific projects.

Getting Started with 3D Printing

Getting started with 3D printing involves understanding key components and selecting the right setup. Beginners need to know the critical factors influencing their 3D printing experience.

Choosing the Right 3D Printer

Selecting a printer depends on the intended use. Fused Deposition Modeling (FDM) printers suit hobbyists and beginners who want to create everyday items. Stereolithography (SLA) printers excel for those needing high detail, ideal for intricate designs. Assessing budget remains crucial; entry-level FDM printers start at around $200, while SLA options begin at approximately $400. Researching each printer’s specifications helps users choose the right model based on accuracy, build size, and ease of use, ensuring successful projects from the start.

Essential 3D Printing Materials

Familiarizing with different materials enhances project outcomes. PLA (Polylactic Acid) offers ease of use and biodegradability, making it suitable for beginners. ABS (Acrylonitrile Butadiene Styrene) provides strength and durability, but it requires a heated print bed. PETG (Polyethylene Terephthalate Glycol) balances flexibility and strength, often used for functional parts. For high-detail applications, resin may be preferred due to its fine resolution. Understanding properties helps users select materials that match their design requirements and printing methods, leading to successful and sustainable results.

Designing for 3D Printing

Designing for 3D printing involves understanding software and effective design techniques. Beginners can create functional objects by mastering these elements.

Software Options for Beginners

Free and accessible software serves as an excellent starting point for beginners. Blender offers versatile modeling tools suitable for various designs. Tinkercad provides a user-friendly interface, ideal for those just getting started. Fusion 360, while more advanced, features powerful design capabilities for hobbyists aiming to grow their skills. Each software option supplies tutorials that help users navigate initial projects and improve their design process.

Tips for Effective 3D Design

Effective design requires attention to detail and consideration of printing limitations. First, ensure models are manifold to avoid printing errors. Second, incorporate proper support structures when necessary to maintain stability during printing. Third, optimize the dimensions to fit within the printer’s build volume. Fourth, consider the material properties, as they influence the final object’s strength and durability. Lastly, reviewing designs with community feedback can provide valuable insights and encourage improvements.

Common Challenges in 3D Printing

3D printing presents several challenges that beginners often encounter. Understanding these challenges helps streamline the printing process and enhances overall success.

Troubleshooting Printing Issues

Printing issues can arise due to various factors. First, bed adhesion often causes problems; models may not stick properly, leading to failed prints. Adjusting the bed level or using adhesion aids can resolve this. Second, layer shifting occurs when the print head misaligns, usually due to loose belts or insufficient torque. Tightening belts resolves this issue. Third, the nozzle may clog, affecting material flow. Regularly cleaning the nozzle prevents this. Fourth, under-extrusion can lead to weak structures. Ensuring the filament is suitable, and the printer’s settings are correctly calibrated solves this problem. Addressing these common issues contributes significantly to successful prints.

Maintaining Your 3D Printer

Maintenance is crucial for optimal printer performance. Regularly checking the printer’s components ensures long-lasting functionality. First, users should clean the print bed before each print to maintain adhesion quality. Second, inspecting the nozzle and extruder regularly prevents clogs and material jams. Third, lubricating the rails helps reduce friction, resulting in smoother movements. Additionally, monitoring the filament storage extends its shelf life and prevents moisture absorption. Lastly, keeping the printer’s firmware updated can improve performance and features. Adopting these maintenance practices leads to better print quality and reliability.

Conclusion

3D printing opens up a world of possibilities for anyone eager to create. With the right knowledge and tools beginners can easily navigate this innovative technology. Understanding the mechanics and selecting the appropriate printer and materials are crucial steps in the journey.

As they explore design software and tackle common challenges they’ll build confidence and skills. Regular maintenance and troubleshooting will enhance their experience and ensure high-quality prints. Embracing 3D printing not only fosters creativity but also empowers individuals to turn their ideas into reality.