Table of Contents

ToggleIn the world of industrial curing, UV chambers are the unsung heroes, transforming liquids into solid masterpieces faster than you can say “instant gratification.” Whether it’s glossy coatings or durable adhesives, these chambers are the magic ovens that bake your products to perfection. But with so many options out there, choosing the right one can feel like picking a favorite child—impossible!

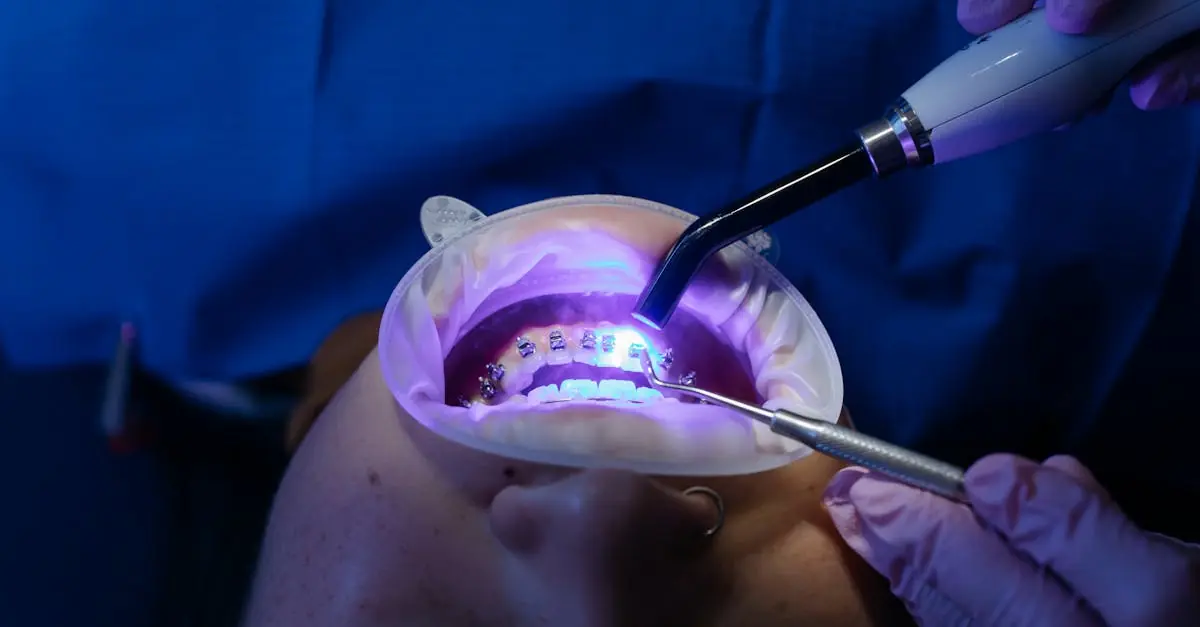

Overview of UV Curing Chambers

UV curing chambers come in various designs and functionalities, tailored for specific industrial applications. Different options cater to unique requirements, such as chamber size, UV light intensity, and curing speed. Small desktop models serve niche markets, while large industrial systems handle substantial production volumes.

Chamber types include conveyorized systems, where moving substrates pass under fixed UV lamps, ensuring consistent exposure. Batch systems, by contrast, accommodate larger items that require stationary curing. Each design possesses unique advantages, making it essential to assess project needs to determine the most suitable option.

Material compatibility plays a crucial role in selection. Some chambers are engineered for specific substrates, such as plastics or metals, while others accommodate a broader range. It’s important to consider the curing chemistry, as different formulations react differently under UV light.

Energy efficiency is another factor influencing the choice of chamber. Many modern units use LED technology, providing longer life and lower energy consumption compared to traditional mercury lamps. Selecting the right light source contributes to reduced operational costs and environmental impact.

Safety features are paramount in UV curing chambers. Considerations include adequate shielding, monitoring systems, and ventilation to protect users from harmful UV radiation and fumes produced during curing. Regulatory compliance ensures that chosen systems meet industry safety standards.

Flexibility also varies among models, with some chambers offering adjustable settings for intensity and curing duration. Customization options enable users to optimize processes according to specific project needs. Overall, understanding the nuances of each UV curing chamber option ensures effective selection for successful industrial applications.

Types of UV Curing Chamber Options

Various UV curing chamber options exist to cater to different industrial needs. Each type offers distinct features and benefits, making it essential to understand their applications.

Benchtop UV Curing Chambers

Benchtop UV curing chambers provide an efficient solution for small-scale operations. Typically designed for compact spaces, these units handle limited production volumes effectively. Many users appreciate their portability and ease of use. These chambers often cater to niche markets, including electronics and small component manufacturing. Versatile in application, they accommodate different substrates and curing materials. Depending on specific requirements, users can select options with adjustable intensity settings for enhanced flexibility.

Industrial UV Curing Chambers

Industrial UV curing chambers excel in high-capacity production environments. These larger systems support substantial manufacturing processes and are ideal for companies with higher output demands. Equipped with conveyorized systems, these chambers ensure continuous curing, greatly increasing workflow efficiency. Many designs include advanced monitoring systems for safety and operational integrity. Optimized for various substrates, they work seamlessly across multiple applications, such as coatings, adhesives, and inks. Energy-efficient options often incorporate LED technology, promoting lower operational costs and longer equipment life.

Key Features to Consider

Selecting the right UV curing chamber involves several critical features that directly impact efficiency and effectiveness.

Size and Capacity

Size significantly affects chamber efficiency. Smaller units suit limited production, making them ideal for niche projects like electronics or crafts. Larger systems support extensive production runs, offering higher throughput for industrial applications. Evaluating available space enhances the integration of a UV curing chamber into an existing production line. Consideration of chamber dimensions paired with the required input and output capacity ensures alignment with production goals. Businesses benefit from understanding their operational needs to avoid under-specification or overcapacity.

UV Lamp Types

UV lamp types influence the curing process. Mercury vapor lamps deliver high-intensity UV light, making them suitable for a range of applications. On the other hand, LED lamps operate at lower temperatures, prolonging equipment life and reducing energy costs. Moreover, LED lamps provide specific wavelengths tailored for various curing materials. Each type carries advantages that cater to distinct project requirements. Evaluating the balance of curing speed, material compatibility, and energy efficiency helps in choosing the appropriate lamp technology for the application.

Benefits of UV Curing Chambers

UV curing chambers offer numerous advantages in industrial applications. They significantly increase production speed by transforming liquids into solids within seconds, enhancing workflow efficiency. Energy efficiency plays a crucial role as many modern chambers use LED technology, which reduces energy consumption and lowers operational costs.

Quality results are often seen with UV curing processes, achieving superior finishes in coatings and adhesives. This high-quality output stems from the precise control of curing parameters, allowing for better consistency across products. Material compatibility is another advantage, enabling the use of various substrates without compromising performance.

Safety is prioritized in chamber designs. Adequate shielding and monitoring systems protect users from harmful UV radiation. Furthermore, flexible settings allow operators to customize curing processes to meet specific project needs effectively.

Convenience increases with the availability of both benchtop and industrial models. Smaller benchtop systems cater to niche markets with limited space, while larger industrial units support extensive production runs through conveyorized systems. Each design meets different operational demands, ensuring that companies can find suitable options for their needs.

Durability is inherent in UV curing chambers. Many units are built to withstand demanding environments, ensuring long-term operation with minimal downtime. By incorporating advanced technology, these chambers offer reliability essential for consistent production quality.

Ultimately, selecting the right UV curing chamber optimizes production processes. It impacts efficiency, safety, and output quality, making careful consideration key to achieving desired results.

Conclusion

Choosing the right UV curing chamber is essential for maximizing production efficiency and ensuring high-quality results. With various options available, from compact benchtop models to large industrial systems, businesses can find a solution tailored to their specific needs.

Considerations like material compatibility and energy efficiency play a significant role in the selection process. Safety features are equally important to protect users from UV exposure. By carefully assessing these factors, companies can enhance their workflows and achieve superior curing outcomes, ultimately driving success in their operations.